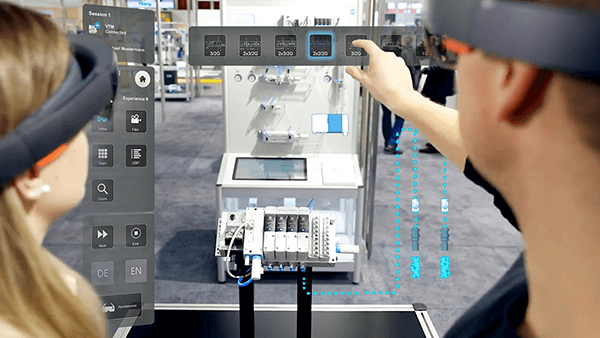

Maintenance and full control of Festo’s motion terminal thanks to AR

OPC-UA enables the exchange of communication from one machine to another. Holo-Light created an interface between HoloLens and OPC-UA which makes this fascinating case study possible.

Festo’s Motion Terminal VTEM, a complex pneumatic device, offers an excellent opportunity to explore the various possibilities when integrating machine data into a Mixed Reality interface.

One possibility is that you can gather information on a 3D model and have all of its data visualized as an overlay on the real object. To figure out if something is wrong with the VTEM, you can run a diagnostic which highlights potential problems on the machine and displays step by step instructions to properly fix errors.

If this doesn’t solve the problem, you can also make a service call with your head-mounted display and let an expert guide you through the necessary steps to repair the machine.

Additionally, the interface between HoloLens and OPC-UA enables you to view live or historical data of the model and even makes control of the machine through HoloLens possible.

| Problem | No immediate access to machine data or expertise to properly maintain machinery |

| Solution | Interface which allows you to retrieve all necessary information in various ways |

| Benefit | Substantial reduction of default rate and assurance of continuous workflows |